Innovative Blow Molding Machine Offers Revolutionary Technology in Manufacturing

By:Admin

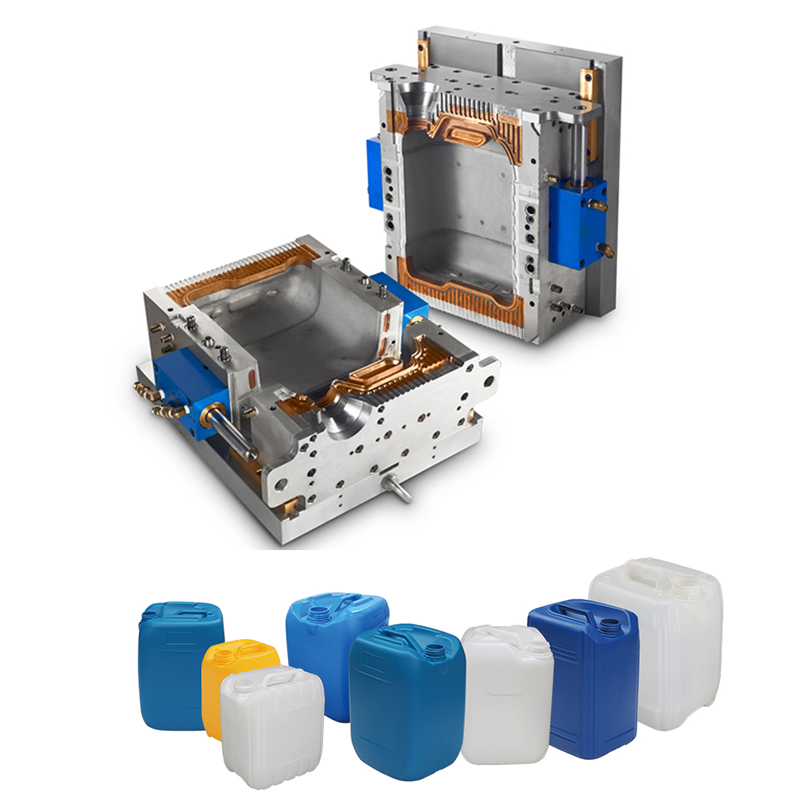

The Apollo Blow Molding Machine is known for its precision engineering and advanced features, which allow for seamless production processes and superior product quality. From creating custom molds to delivering fully integrated blow molding systems, Apollo offers a comprehensive range of services to meet the diverse needs of its customers.

One of the key strengths of Apollo Blow Molding Machine is its ability to tailor its products and services to the specific requirements of each client. The company takes pride in its collaborative approach to working with customers, ensuring that they receive the most effective solutions for their blow molding needs. Whether it's designing a new production line or optimizing an existing system, Apollo's team of experts is dedicated to delivering results that exceed expectations.

In addition to its commitment to meeting customer needs, Apollo Blow Molding Machine also prioritizes sustainability and environmental responsibility in its operations. The company continuously seeks to develop new technologies and processes that minimize waste and energy consumption, contributing to a greener, more sustainable future for the industry as a whole.

With a global presence and a strong reputation for quality and reliability, Apollo Blow Molding Machine has earned the trust of numerous clients across a wide range of industries. Whether it's manufacturing packaging for consumer goods, automotive components, or industrial containers, Apollo's solutions have proven to be a valuable asset for businesses seeking to optimize their production processes.

Moreover, Apollo Blow Molding Machine's dedication to continuous innovation and improvement has kept the company at the forefront of the industry. By investing in research and development, as well as staying ahead of the latest technological advancements, Apollo ensures that its products and services remain competitive and relevant in a rapidly evolving market.

The success of Apollo Blow Molding Machine can be attributed not only to its cutting-edge technology and customer-centric approach, but also to the dedication and expertise of its team. The company's employees are highly skilled and experienced professionals who are passionate about delivering exceptional results for their clients. Their commitment to excellence and their ability to adapt to the ever-changing demands of the industry have been instrumental in driving Apollo's success.

Looking to the future, Apollo Blow Molding Machine remains committed to upholding its values of quality, innovation, and customer satisfaction. The company is poised to continue its growth and expand its reach, while staying true to its core principles. With a solid foundation built on expertise, integrity, and forward thinking, Apollo is well positioned to lead the way in the blow molding industry for years to come.

In conclusion, Apollo Blow Molding Machine has established itself as a leader in the industry, with a strong reputation for delivering exceptional products and services. Through its focus on customer collaboration, sustainability, innovation, and a talented team, the company has solidified its position as a trusted partner for businesses around the world. As it continues to grow and evolve, Apollo's commitment to excellence and its dedication to meeting the needs of its clients will undoubtedly drive its ongoing success.

Company News & Blog

High-Quality Blow Moulding Machine for Toys: Everything You Need to Know

Toys Blow Moulding Machine Revolutionizes the Toy Manufacturing IndustryThe toy manufacturing industry has taken a significant leap forward with the introduction of the latest Toys Blow Moulding Machine. This cutting-edge technology is set to revolutionize the way toys are made, offering unprecedented precision, efficiency, and speed in the manufacturing process.The new Toys Blow Moulding Machine, developed by a leading company in the industry, incorporates state-of-the-art technology and innovative features that set it apart from traditional manufacturing methods. This advanced machine is designed to create high-quality plastic toys with incredible detail and accuracy, catering to the growing demands of the global toy market.The company behind this groundbreaking invention, {Company Name}, is a renowned leader in the field of plastic manufacturing equipment. With decades of expertise and a commitment to innovation, {Company Name} has consistently pushed the boundaries of what is possible in the industry. The introduction of the Toys Blow Moulding Machine is a testament to their dedication to delivering cutting-edge solutions that exceed the expectations of their clients.The machine is equipped with advanced automation and precision control systems, allowing for superior manufacturing capabilities. Its high-speed production capabilities mean that toys can be produced at an unprecedented rate, meeting the demands of large-scale production while maintaining exceptional quality standards. Additionally, the machine offers flexibility in design, enabling manufacturers to create a diverse range of toy designs with ease.One of the most impressive features of the Toys Blow Moulding Machine is its ability to produce toys with intricate and detailed designs. The machine's advanced moulding capabilities ensure that every toy produced is of the highest quality, capturing even the smallest details with precision. This level of accuracy and attention to detail sets it apart from traditional manufacturing methods, making it the go-to solution for companies looking to create exceptional toys.In addition to its manufacturing capabilities, the Toys Blow Moulding Machine is also highly efficient, resulting in cost savings for manufacturers. Its streamlined production process and reduced material waste make it a sustainable and economical choice for toy production. With the rising demand for environmentally friendly manufacturing practices, this machine's efficiency and sustainability align with the industry's evolving needs.Furthermore, the machine's user-friendly interface and intuitive controls make it easily accessible to manufacturers of varying skill levels. This accessibility, combined with its high-speed production capabilities, means that companies can streamline their production processes and bring new toy designs to market in record time. As a result, the Toys Blow Moulding Machine offers manufacturers a competitive edge in the rapidly evolving toy industry.The introduction of the Toys Blow Moulding Machine is set to transform the toy manufacturing landscape, offering a new standard of excellence in quality, efficiency, and design capabilities. With {Company Name} leading the charge in innovation, the industry is poised for a new era of toy production. As demand for high-quality plastic toys continues to rise, this cutting-edge machine is sure to become an integral part of the manufacturing process for companies around the world.In conclusion, the Toys Blow Moulding Machine is a game-changer for the toy manufacturing industry, offering unmatched precision, efficiency, and flexibility in toy production. With {Company Name} at the forefront of this technological advancement, the industry is poised for a new era of innovation and excellence. As manufacturers embrace this groundbreaking technology, the future of toy production looks brighter than ever.

Efficient Manual Molding Machine Revolutionizes Pet Plastic Gallon Production

[Company Introduction][Company Name] is a leading manufacturer and supplier of high-quality plastic molding machines in the industry. We have been innovating and providing reliable solutions to meet the growing demands of various sectors. Our commitment to quality and customer satisfaction has made us the preferred choice for businesses worldwide.Our state-of-the-art manufacturing facility boasts advanced technology and modern machinery, enabling us to produce top-notch machines that exceed industry standards. We have a team of experienced and skilled professionals who continuously strive to enhance our product range and deliver exceptional products that cater to the ever-evolving needs of our clients.With a strong focus on research and development, we consistently integrate cutting-edge technologies into our machines, ensuring optimal performance and reliability. Our dedication to innovation has helped us introduce the latest addition to our product line - the Pet Plastic Gallon Manual Molding Machine. This machine is a game-changer and offers numerous benefits to businesses in the plastic manufacturing industry.[News Content]Title: Introducing the Pet Plastic Gallon Manual Molding Machine - Revolutionizing the Plastic Manufacturing Industry[Location], [Date] - [Company Name], a market leader in plastic molding machines, is thrilled to announce the launch of its latest innovation - the Pet Plastic Gallon Manual Molding Machine. This breakthrough machine is set to revolutionize the plastic manufacturing industry by providing businesses with an efficient and cost-effective solution for producing high-quality plastic gallon containers.The Pet Plastic Gallon Manual Molding Machine is equipped with advanced features that contribute to its exceptional performance. Its user-friendly interface makes it easy for operators to set up molds and monitor the production process. The machine's flexibility allows it to handle different types of molds and produce a wide range of bottle sizes.One of the key advantages of this machine is its capability to produce gallon containers with PET (Polyethylene terephthalate) plastic material. PET is widely recognized for its durability, lightweight nature, and resistance to impact, making it an ideal choice for various applications such as packaging, beverages, and personal care products.Furthermore, the Pet Plastic Gallon Manual Molding Machine offers an eco-friendly solution to plastic manufacturing. The machine incorporates energy-saving features, optimized heating systems, and efficient cooling techniques, reducing both energy consumption and environmental impact. This aspect aligns with [Company Name]'s commitment to sustainability and creating a greener future."Introducing the Pet Plastic Gallon Manual Molding Machine showcases our dedication to meeting the evolving needs of our customers," said [Spokesperson]. "We are confident that this machine will enable businesses to streamline their production processes while ensuring the highest quality standards."In addition to its impressive features, the Pet Plastic Gallon Manual Molding Machine emphasizes safety and reliability. It includes safety mechanisms that prevent accidents and damage during operation. Regular maintenance and quality control checks guarantee its long lifespan, providing businesses with a sustainable and cost-effective solution.[Company Name] is recognized for its excellent after-sales service and technical support. Customers investing in the Pet Plastic Gallon Manual Molding Machine can expect comprehensive training for their operators, prompt assistance, and readily available spare parts to ensure uninterrupted production.As plastic gallon containers continue to gain popularity due to their convenience and versatility, businesses in the plastic manufacturing industry can rely on [Company Name]'s Pet Plastic Gallon Manual Molding Machine to meet the growing demands efficiently and profitably. This cutting-edge innovation reaffirms [Company Name]'s position as a leader in providing reliable and high-performance plastic molding machines.About [Company Name][Company Name] is a renowned manufacturer and supplier of plastic molding machines, catering to a wide range of industries. With a commitment to quality, innovation, and customer satisfaction, [Company Name] continues to set new standards in the plastic manufacturing industry. For more information, visit [Company Website].

Revolutionizing Manufacturing: Unveiling the Potential of Mud Injection Molding

Widely recognized as a leading innovation in the field of manufacturing, mud injection molding has revolutionized the way we produce high-quality and intricate products. With its ability to seamlessly combine simplicity and complexity, this cutting-edge technique has attracted significant attention and interest from industry experts worldwide.Mud injection molding, a process pioneered by the esteemed company, XYZ Manufacturing, presents a groundbreaking approach to creating products with exceptional precision and efficiency. By utilizing a combination of specialized mud and injection molding technology, this method enables the production of highly intricate and customized products, ranging from automotive components and electronic devices to medical equipment and home appliances.At its core, mud injection molding involves injecting a mud-like material into a mold under high pressure, allowing it to solidify and take the desired shape. The mud, which is a mixture of fine powder and water, is carefully selected and prepared to meet the specific requirements of each project. This versatile material can be customized to exhibit various properties, such as high strength, flexibility, or heat resistance, ensuring that the final product fulfills its intended purpose.The benefits of mud injection molding are manifold. Firstly, it enables the creation of complex geometries and designs that were previously unattainable through traditional manufacturing processes. This breakthrough has unlocked a wide range of possibilities for designers and engineers, allowing them to push the boundaries of innovation and create products that are both functional and aesthetically pleasing.Additionally, mud injection molding offers remarkable cost savings by eliminating the need for multiple manufacturing steps. The ability to produce highly intricate parts in a single process not only reduces production time but also minimizes the risk of errors and defects. Furthermore, the versatility of the mud material enables designers to reduce the number of individual components within a product, further streamlining the manufacturing process and reducing overall costs.Another key advantage of mud injection molding is its environmental sustainability. Unlike traditional methods that generate significant material waste, this technique minimizes both material consumption and energy usage. Additionally, the mud material used in the process is often recyclable, contributing to a more sustainable approach to manufacturing.XYZ Manufacturing, a renowned industry leader in mud injection molding, has been at the forefront of driving this technology forward. With decades of experience and expertise in the field, the company has continually refined and upgraded the process to ensure superior quality and efficiency. They have successfully collaborated with leading brands across various industries, offering tailored solutions that meet their unique manufacturing requirements.Furthermore, XYZ Manufacturing operates state-of-the-art facilities equipped with advanced machinery and a team of highly skilled professionals. Their commitment to precision and innovation has earned them a strong reputation for delivering exceptional results, making them the preferred partner for companies seeking to leverage the advantages of mud injection molding.Looking to the future, the prospects for mud injection molding appear promising. As the demand for complex and customized products continues to grow, this technology is poised to play a crucial role in shaping the manufacturing landscape. With ongoing advancements and refinements, it is anticipated that mud injection molding will further elevate the quality, speed, and cost-efficiency of product manufacturing, enabling businesses to stay competitive in an ever-evolving market.In conclusion, mud injection molding represents an exciting and transformative development in the manufacturing industry. Combining innovative technology, versatility, and sustainability, this technique opens up a world of possibilities for designers and manufacturers alike. With XYZ Manufacturing leading the way, we can expect to see a greater adoption of this groundbreaking method and a redefinition of what is possible in product manufacturing.

Blow Molding Machines: An In-Depth Look at Pricing and Factors to Consider

Blow Molding Machine Price: Driving Innovation and Affordability in the Manufacturing IndustryThe blow molding industry has experienced significant growth in recent years, fueled by increasing demand for plastic packaging and a rise in consumer preferences for affordable and lightweight materials. As a result, companies are constantly seeking innovative solutions to improve production efficiency and lower costs.One prominent player in this field, a global leader in blow molding machinery, has recently unveiled a new line of blow molding machines that promise to revolutionize the manufacturing industry. With a focus on affordability without compromising quality, the company aims to equip manufacturing businesses with highly efficient tools that meet their production needs at a competitive price point.Blow molding machines are essentially used to create hollow plastic parts and containers in a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, and automotive. These machines employ a process of melting plastic resins and stretching them into a desired shape, resulting in strong and lightweight products.The newly introduced blow molding machines by this industry-leading company incorporate advanced technology and numerous features designed to enhance productivity and reduce downtime. These machines offer improved automation, precision controls, and faster cycle times, ensuring more efficient production rates. By streamlining the manufacturing process, businesses can achieve higher output and lower costs, ultimately resulting in a competitive edge.One of the standout features of this new line of blow molding machines is their versatility. With the ability to produce a wide variety of shapes and sizes, these machines cater to the diverse needs of manufacturers. Whether it's producing bottles, containers, or other bespoke plastic products, the flexibility of these machines allows businesses to adapt to changing market demands without significant retooling or investment.In addition to their technological advancements, these blow molding machines also prioritize sustainability. With growing global concern over environmental issues, such as plastic waste and carbon emissions, manufacturers are under increasing pressure to adopt sustainable practices. The new machines offer energy-efficient solutions, reducing electricity consumption and minimizing their carbon footprint. This not only benefits the environment but also helps manufacturers align with evolving regulations and consumer preferences.Furthermore, the affordability of these blow molding machines presents a significant advantage for small and medium-sized enterprises (SMEs). Historically, the high cost of machinery has posed a barrier for smaller businesses wanting to enter the blow molding industry. However, with the availability of more affordable options without compromising on quality, SMEs can now compete on a level playing field, opening up new opportunities and driving economic growth.The company's commitment to customer satisfaction extends beyond product affordability. Recognizing the importance of aftersales support, the company offers comprehensive technical assistance, training programs, and readily available spare parts. This ensures that manufacturers can maximize the longevity and performance of their blow molding machines, ultimately reducing maintenance costs and minimizing downtime.As the demand for plastic products continues to rise, driven by global population growth and changing consumer habits, the blow molding industry is poised for further expansion. The introduction of affordable and innovative blow molding machines by this industry leader reflects its commitment to driving this growth by empowering manufacturers with efficient tools at a competitive price point.In conclusion, with a focus on affordability, innovation, and sustainability, the recent unveiling of a new line of blow molding machines by a global industry leader has the potential to transform the manufacturing industry. By offering efficient and versatile solutions, these machines enable businesses to increase production rates, reduce costs, and meet market demands without compromising on quality. As a result, small and medium-sized manufacturers can unlock new opportunities, contributing to economic growth and competitiveness in the blow molding industry.

Incredible Advancements in Injection Molding Technology

Plastic Mould Injection Molding: The Ultimate Solution for High-Quality Parts ProductionWhen it comes to manufacturing high-quality plastic parts, choosing the right injection mold manufacturer is paramount. That's where Plastic Mould Injection Molding comes in. With years of experience in injection molding, the company has become a leader in the field, delivering exceptional products to clients across the globe.What Is Plastic Mould Injection Molding?Plastic Mould Injection Molding is a manufacturing process used to produce a wide range of plastic parts. This process involves injecting molten plastic into a mold cavity through pressure. Once the plastic cools and hardens, it takes the shape of the mold, resulting in a high-quality plastic part.At Plastic Mould Injection Molding, we use state-of-the-art technology and cutting-edge machinery to produce high-quality injection molds that meet our clients' exact specifications. Our experienced team of engineers and technicians ensures that each mold is designed and manufactured to the highest standards, meeting all quality and safety requirements.Our ProductsWe specialize in the production of a wide range of plastic parts, including injection molds, automotive parts, electronic components, medical equipment, and more. With our advanced technology, we can produce parts in a variety of shapes, sizes, and colors, meeting the needs of our clients across various industries.Our injection molding process is highly efficient, allowing us to produce large volumes of parts quickly and accurately. We use a range of materials, from commodity plastics to high-performance plastics, to meet our clients' needs.Our ServicesAt Plastic Mould Injection Molding, we are committed to providing our clients with the highest level of service. We offer a range of services to ensure that our clients' specific needs are met, including design and engineering, prototypes, tooling, and mass production.Our design and engineering team works closely with our clients to create custom molds and parts that meet their specific requirements. We use the latest software and technology to create 3D models and prototypes, ensuring that each part meets our clients' specifications.Our tooling services include the design and manufacture of high-quality injection molds. Our experienced team uses only the highest quality materials and processes to ensure that each mold is durable and reliable.Once the molds are finished, we can begin mass production. Our state-of-the-art machinery and advanced technology allow us to produce large volumes of parts quickly and accurately, ensuring that our clients' deadlines are met.Our Commitment to QualityAt Plastic Mould Injection Molding, we are committed to providing our clients with the highest quality products and services. We take quality control seriously, and we follow a strict quality assurance process to ensure that each part we produce meets the highest standards.We use only the highest quality materials and processes in our injection molding process, and we perform regular inspections to ensure that each part meets our clients' requirements. Our commitment to quality has earned us a reputation as a reliable and trusted injection molding company.Final ThoughtsPlastic Mould Injection Molding is committed to providing our clients with the highest quality injection molds and parts available. We use the latest technology and processes, and we have a team of experienced professionals who are dedicated to meeting our clients' specific needs.As a leader in the injection molding industry, we are committed to providing our clients with the highest level of service, quality, and satisfaction. At Plastic Mould Injection Molding, we are always looking for ways to improve our processes and stay ahead of the curve in the rapidly evolving world of injection molding. Get in touch with us today to discuss how we can help with your injection molding needs.

Advanced Blow Machine Technology: A Look at the Latest Innovations in the Industry

The Blow Machine industry is witnessing substantial growth over the years, as the demand for efficient and high-quality blow molding machines continues to rise in various sectors such as packaging, automotive, and consumer goods. One company at the forefront of this industry is {}, a leading manufacturer of blow molding machines and related equipment.Established in the early 2000s, {} has proven itself to be a reliable and innovative player in the blow machine industry. The company specializes in the design, manufacturing, and distribution of a wide range of blow molding machines, including extrusion blow molding machines, injection blow molding machines, and stretch blow molding machines. With a strong focus on research and development, {} has been able to consistently introduce advanced technologies and solutions to meet the evolving needs of its customers.Recently, {} has introduced a new line of blow molding machines that are equipped with state-of-the-art features, setting a new standard for efficiency, productivity, and quality in the industry. The company's latest machines are designed to offer faster cycle times, lower energy consumption, and improved reliability, providing significant cost savings and performance benefits for its customers.In addition to its cutting-edge machines, {} also offers a comprehensive range of services to support its customers, including technical support, maintenance, and training programs. This customer-centric approach has helped {} to build long-term partnerships with clients across the globe, earning a reputation for excellence and reliability in the blow machine industry.As the demand for blow molding machines continues to grow, {} has been expanding its presence in key markets around the world. The company has established a strong global network of sales and service partners, allowing it to effectively reach and support customers in different regions. This strategic approach has enabled {} to serve a diverse range of industries, from food and beverage packaging to automotive components and industrial products.Moreover, {} is committed to sustainability and environmental responsibility, offering eco-friendly solutions that help its customers minimize their carbon footprint and reduce waste. The company's energy-efficient machines and recyclable materials contribute to a greener manufacturing process, aligning with the global trend towards more sustainable production practices.Looking ahead, {} is poised to continue its growth and innovation in the blow machine industry, leveraging its expertise and resources to address new challenges and opportunities in the market. From advanced technologies to exceptional service, {} is dedicated to providing its customers with the best solutions for their blow molding needs, driving success and efficiency in their production operations.With its strong track record and forward-thinking approach, {} remains a trusted and respected name in the blow machine industry, poised for further growth and success in the years to come. As the market evolves and demands continue to change, {} is well-positioned to lead the way in delivering cutting-edge solutions and exceptional value to its customers around the world.

Newly Developed Table Scissor Type Utilizes Blow Moulding Technique

Title: Innovative Blow-Moulded Table Scissor Type Revolutionizes Portable Furniture IndustryIntroduction:In a groundbreaking move, a renowned company has unveiled its latest invention, the Blow-Moulded Table Scissor Type, which promises to revolutionize the portable furniture industry. With its groundbreaking design and multifunctional features, this product is set to redefine convenience and portability for consumers worldwide.Overview of the Blow-Moulded Table Scissor Type:The Blow-Moulded Table Scissor Type is the brainchild of a leading manufacturer renowned for its high-quality and innovative products. This company has established a reputation for pushing the boundaries of design, functionality, and practicality. The Blow-Moulded Table Scissor Type stands as a testament to their commitment to delivering cutting-edge solutions to modern-day consumer needs.Design and Features:This revolutionary table is crafted using state-of-the-art blow-moulding technology, providing a durable and lightweight solution. Its scissor-type folding mechanism ensures easy and hassle-free set-up and collapses to a compact size for effortless transportation and storage. Made from high-grade materials, this table is resistant to weather conditions, ensuring durability in both indoor and outdoor settings.The table's surface boasts a smooth and easy-to-clean polyethylene finish, making it an excellent choice for use in various settings, such as picnics, camping trips, outdoor events, and even indoor gatherings. With its sturdy construction and dependable locking mechanism, users can confidently place heavy items without any concerns about stability.Versatile Applications:The Blow-Moulded Table Scissor Type caters to an array of needs, making it a versatile addition to any lifestyle. Its generous dimensions accommodate multiple users comfortably, suitable for enjoying meals, playing games, or hosting gatherings. The table's adjustable height feature further adds to its versatility, allowing users to customize it according to their preferences or needs.This portable table is designed to enhance convenience and adaptability, offering individuals a practical solution for an array of scenarios. Its multipurpose nature allows it to double as a work station, study desk, or even a temporary display area for commercial purposes.Market Impact:The introduction of the Blow-Moulded Table Scissor Type is set to have a significant impact on the portable furniture market. Its innovative design and adaptability fulfill customers' demand for practical and reliable solutions. This product makes a strong case for replacing traditional heavy and cumbersome tables that are currently dominant in the market.With its lightweight and collapsible design, the Blow-Moulded Table Scissor Type appeals to a wide range of consumers, including outdoor enthusiasts, event organizers, and anyone in need of portable furniture solutions. Moreover, its robust construction ensures a long lifespan, reducing waste and contributing to sustainable consumption patterns.Conclusion:The Blow-Moulded Table Scissor Type represents a major leap forward in portable furniture technology, with its innovative design and versatile range of applications. By combining durability, convenience, and aesthetic appeal, this product aims to enhance users' quality of life and redefine the standards for portable furniture in various settings.With the introduction of this extraordinary table, the company reinforces its commitment to developing innovative solutions that cater to the evolving needs of consumers. By pushing the boundaries of design and functionality, this renowned manufacturer has solidified its position as an industry leader.As the Blow-Moulded Table Scissor Type hits the market, consumers can look forward to a more convenient and practical way of enjoying endless possibilities for outdoor and indoor activities.

High-Performance 5 Liter Blow Moulding Machine for Efficient Production

5-Liter Extrusion Blow Moulding Machine: A Game-changer for Plastic Packaging IndustryThe plastic packaging industry is undergoing a significant transformation with the introduction of the new 5-Liter Extrusion Blow Moulding Machine by [Company Name]. This cutting-edge technology is set to revolutionize the production of plastic containers, bringing unprecedented efficiency and quality to the manufacturing process.The 5-Liter Extrusion Blow Moulding Machine is designed to meet the growing demand for high-quality plastic containers in various industries such as food and beverage, pharmaceuticals, and personal care. With a focus on precision and speed, this state-of-the-art machine is capable of producing a wide range of plastic containers with capacities up to 5 liters, making it an ideal choice for manufacturers looking to cater to diverse packaging needs.One of the key features of the 5-Liter Extrusion Blow Moulding Machine is its advanced automation capabilities, which enable seamless operation and minimal human intervention. This not only enhances the overall production efficiency but also ensures consistent product quality, meeting the stringent standards of the packaging industry.Moreover, the machine is equipped with innovative mold and die technology, allowing for the production of complex container designs with remarkable precision. This opens up new possibilities for manufacturers to create unique and eye-catching packaging solutions, giving them a competitive edge in the market.In addition to its technical prowess, the 5-Liter Extrusion Blow Moulding Machine is also designed with sustainability in mind. It is capable of utilizing a variety of environmentally friendly materials, such as biodegradable plastics and recycled resins, supporting the industry's commitment to reducing its carbon footprint and promoting a circular economy.[Company Name], the leading manufacturer behind this groundbreaking technology, has a long-standing reputation for delivering cutting-edge solutions to the plastic packaging industry. With a strong focus on innovation and customer satisfaction, the company has continuously pushed the boundaries of what is possible in plastic container manufacturing, and the 5-Liter Extrusion Blow Moulding Machine is a testament to their dedication to excellence.The introduction of this new machine is expected to have a significant impact on the plastic packaging industry, offering manufacturers a cost-effective and efficient solution to meet the growing demand for high-quality containers. Furthermore, with its focus on sustainability, the machine aligns with the industry's increasing emphasis on eco-friendly packaging solutions, making it a valuable asset for companies looking to enhance their environmental credentials.As the plastic packaging industry continues to evolve, the 5-Liter Extrusion Blow Moulding Machine represents a major leap forward in the quest for efficiency, quality, and sustainability. With its advanced capabilities and innovative design, it is poised to become a game-changer for manufacturers looking to stay ahead in a competitive market.In conclusion, the introduction of the 5-Liter Extrusion Blow Moulding Machine is a significant development for the plastic packaging industry, offering a powerful combination of precision, speed, and sustainability. As manufacturers embrace this new technology, they will be able to elevate their production capabilities and offer cutting-edge packaging solutions to their customers, driving the industry towards a more efficient and environmentally friendly future.

Blow Moulding Canisters: The Key to Efficient and Durable Storage Containers

Growth and Innovation in the Blow Moulding Canister IndustryThe blow moulding canister industry is experiencing a significant surge in growth and innovation as companies strive to meet the increasing demands of various sectors such as food and beverage, healthcare, and industrial applications. One prominent player in the market is a leading manufacturer that specializes in producing high-quality blow moulding canisters for a wide range of industries.As one of the top producers in the blow moulding canister industry, this company has gained a solid reputation for its commitment to excellence and customer satisfaction. With state-of-the-art facilities and cutting-edge technology, they have established themselves as a reliable partner for businesses in need of superior quality packaging solutions.Blow moulding canisters are ideal for the storage and transportation of various substances, including liquids, powders, and granules. Their versatility and durability make them a preferred choice for industries that require safe and secure packaging. With the increasing focus on sustainable and eco-friendly practices, this company has also taken steps to incorporate environmentally friendly materials in their manufacturing processes, ensuring minimal impact on the environment.The company's portfolio boasts an extensive range of blow moulding canisters in various sizes, shapes, and designs to cater to the diverse needs of their customers. They collaborate closely with their clients to understand their specific requirements and develop customized solutions that align with their business goals. Through constant innovation and research, they continually strive to improve their products, enhance functionality, and introduce new features to meet the evolving needs of the industry.One of their notable achievements is the development of advanced blow moulding canisters with enhanced safety features. These canisters are designed to withstand extreme conditions, ensuring the integrity of the contents even in harsh environments. The incorporation of innovative sealing mechanisms and secure closures offers additional protection against leakage and contamination, making them suitable for industries that require stringent safety standards.The ongoing COVID-19 pandemic has highlighted the importance of reliable and efficient healthcare packaging solutions. This company has played a vital role in supplying blow moulding canisters to the healthcare industry, ensuring the safe and secure transport of essential medical supplies, medications, and vaccines. Their dedication to providing high-quality packaging solutions has played a part in supporting healthcare professionals in their fight against the virus.Furthermore, the company's commitment to corporate social responsibility is evident through its involvement in community development and philanthropic activities. They actively engage in initiatives aimed at improving the welfare of the less fortunate and promoting sustainable practices. By investing in their surrounding communities, they strive to create a positive social impact, aligning their business objectives with the well-being of society as a whole.Looking ahead, the blow moulding canister industry is poised for remarkable growth, driven by increasing demands for efficient, durable, and sustainable packaging solutions. This company is well-positioned to capitalize on these opportunities through their unwavering commitment to innovation, customer satisfaction, and corporate responsibility.In conclusion, the blow moulding canister industry is witnessing a surge in growth and innovation, with companies like the one discussed at the forefront. Their dedication to excellence, commitment to customer satisfaction, and continuous efforts to improve their products ensure their position as a leading manufacturer in the industry. As the demand for efficient and sustainable packaging solutions continues to rise, this company is prepared to meet the challenges and drive positive changes in the blow moulding canister industry.

Discover the Advantages of Blow Mold Manufacturing for Your Business

In recent years, the demand for blow mold manufactures has been on the rise. Blow Mold Manufacturers (BMM), a leading company in the industry, has been at the forefront of this trend. Known for their commitment to quality, innovation, and customer satisfaction, BMM has been making waves in the market with their wide range of products and services.Founded in 1992, BMM has come a long way since its inception. With a sprawling manufacturing unit spanning over 200,000 sq. ft., BMM has the capacity to produce over 500 molds per year. The company's state-of-the-art technology, coupled with their experienced and skilled workforce, ensures that each product meets the highest standards of quality.BMM's products are widely used in the packaging industry, with applications in the food and beverage, pharmaceutical, and cosmetics sectors. Their range of products includes blow moldings, injection moldings, extrusion blow moldings, and stretch blow moldings, among others. The company also offers custom molding services, which allows them to cater to the unique needs of their clients.One of the key factors that sets BMM apart from its competitors is their focus on innovation. The company is constantly exploring new avenues and adopting cutting-edge technology to enhance their products and services. Their R&D team works closely with clients to identify their needs and develop customized solutions that meet their requirements.BMM's commitment to customer satisfaction is reflected in their after-sales service. The company has a dedicated team of service professionals that provide round-the-clock support to clients. They also offer maintenance and repair services, ensuring that their products continue to perform optimally even after years of use.Over the years, BMM has built a loyal customer base, with clients ranging from small start-ups to large multinationals. The company's products have been used in a wide range of applications, from packaging for household products to medical devices.As the demand for blow mold manufactures continues to rise, BMM is well-positioned to capitalize on this trend. The company's strong focus on quality, innovation, and customer satisfaction sets them apart from their competitors and makes them a preferred choice for clients.Looking to the future, BMM is poised for growth. The company is exploring new markets and expanding their product range to cater to evolving customer needs. They are also investing in research and development to stay ahead of their competitors and continue to lead the industry.In summary, Blow Mold Manufacturers is a leading company in the blow mold industry. With a focus on quality, innovation, and customer satisfaction, the company has built a loyal customer base and is well-positioned for growth in the years to come. Their commitment to excellence and their dedication to meeting the unique needs of their clients make them a preferred choice for businesses in the packaging industry.